INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- MoD initiates comprehensive review of Defence Acquisition Procedure 2020, pushes for defence reforms

- G7: The Swansong

- Kalinga Connect: South Asia to Polynesia

- Advanced MRSAM for India for a greater firepower

- Must Credit DRDO for Operation Sindoor, now what is next for defence R&D?

- Operation Sindoor | Day 2 DGMOs Briefing

- Operation Sindoor: Resolute yet Restrained

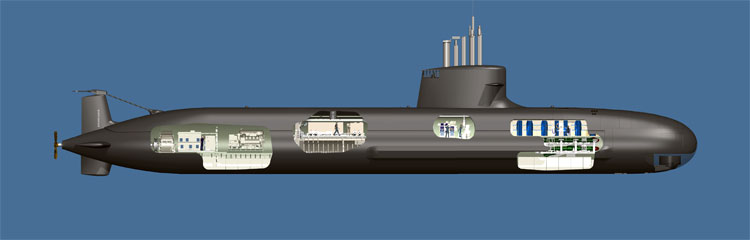

Navantia’s “BEST” AIP (Bio-Ethanol Stealth Technology)

The S-80 Class submarines under construction by Navantia are fitted with Navantia’s proprietary BEST (Bio-Ethanol Stealth Technology) Air Independent Propulsion (AIP). This is the most advanced and revolutionary solution in the market in terms of reliability, endurance and low maintenance, therefore providing very high tactical capabilities to the Spanish Navy.

Achieving this goal has required two decades of rigorous technology development process, a hard and long path not exempt of technical challenge. Nonetheless the final result is very appealing.

Whilst first generation AIPs using Stirling engines have improved over the years, they still represent a very rudimentary and low-efficient solution. Second generation AIPs include a fuel cell which combines an oxidant and fuel to generate power. However, they render a problem with Hydrogen storage, requiring large and heavy hydride cylinders placed outside the submarine and logistic issues for the supply of ultra-pure hydrogen.

Whereas first and second generations AIP systems are still provided in small submarines without ocean going ambitions, the third generation AIPs have been developed for expeditionary submarines. These systems replace hydrogen storage by hydrogen production onboard. This is the solution under development by some suppliers, considering ethanol, methanol or diesel-oil as fuel.

Navantia’s BEST AIP is to be installed into a submarine under construction, the S80 Plus. This is a step forward which emphasizes the uniqueness and maturity of Navantia’s AIP solution.

Navantia’s BEST AIP combine the expertise the Spanish company Abengoa Innovación for the fuel processor, and the American company Collins Aerospace, well known for their work in aerospace for NASA, for the fuel cell. Hydrogen is produced from agricultural bio-ethanol, readily available worldwide, as opposed to other solutions in the market using high-purity diesel oil or methanol.

This challenge required the development by Abengoa of a cutting-edge Hydrogen generator -a high thermal efficiency miniaturized bioethanol processor- to feed a Proton Exchange Membrane (PEM) fuel cell specifically developed, as well, for the S-80 Program by Collins Aerospace. Process fuel gases are managed by the Carbon Dioxide Disposal System designed and developed by Bionet, a Spanish processes engineering company, in collaboration with Navantia. This system provides perfect gas dilution in seawater -avoiding presence of bubbles which could degrade submarine stealthiest- to guarantee an exceptional noise level performance as in pure electric diving.

The fuel cell supplied by Collins Aerospace is specifically developed to military naval specifications, not a commercial based PEM fuel cell adapted for submarine use. The cell stacks are made of porous bipolar plates for passive water management and uniform, continuous membrane humidification (no need for humidification or liquid water removal systems).This advanced design not only makes the fuel cell simpler at the system level, but also provides double service life duration in comparison with the market standard operating on reformate gas and pure Oxygen (not air). This avoids the need for Hydrogen purification systems- such as a membrane- or simulate air, a further simplification of the system.

Often a smoothly run project gets a black eye because of problems during implementation. As opposed to other third generation AIPs in the market, which remain at laboratory level without a project for implementation in the near term, Navantia’s BEST AIP is to be installed into a submarine under construction, the S80 Plus. This is a step forward which emphasizes the uniqueness and maturity of Navantia’s AIP solution.

Long-term (land-based) tests have been completed at a test facility at the Cartagenashipyard (Spain), construction place of the S-80 plus, with a true submarine operational profile, confirming a submerged enduranceof up to three weeks.

Many years of submarine operation experience, submarine design and NASA programs have permitted the development of Navantia’s BEST AIP components. Multi-year collaboration between the Spanish MoD and the Navy, Navantia, Abengoa Innovación and Collins Aerospace has resulted into a very reliable AIP solution, safe and with low maintenance requirements,that uses low-cost easy-sourcing bio-ethanol as fuel.